Analysis

Addressing the Unique Challenges of External PIM on Rooftop Sites

Look around any urban environment, and chances are you’ll see wireless infrastructure brimming from rooftops, stretching across the horizon. Rooftops provide a practical, ubiquitous, and cost-effective solution for deploying wireless infrastructure, especially in densely populated urban and suburban areas where space for macro communication towers is limited. These sites leverage existing structures, reducing the need for new tower deployment and enabling providers to strategically position antennas to enhance coverage and capacity.

However, with this abundance of rooftop wireless sites comes an array of unique challenges. Chief among them is the high prevalence of external passive intermodulation (PIM), which can degrade network performance if not properly assessed and mitigated.

A Refresher on PIM

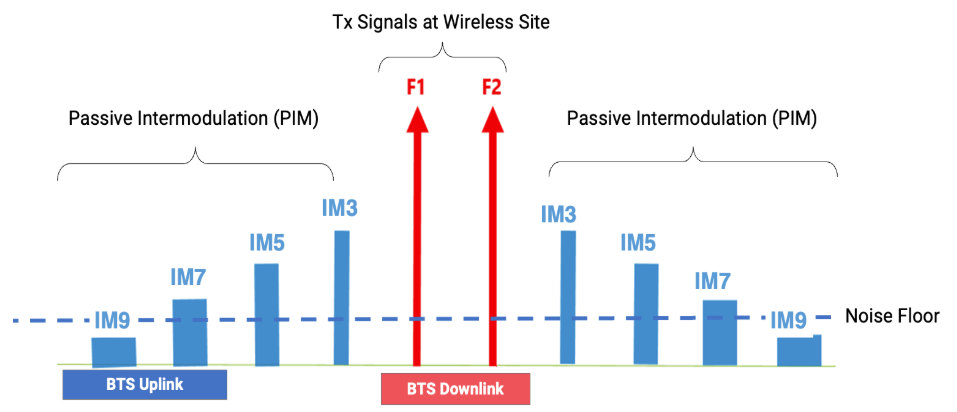

Passive Intermodulation (PIM) refers to the creation of new frequencies generated by transmit signals at a cell site when they encounter non-linearities in the RF path, such as loose connections or damaged components. These unwanted PIM signals can fall within the operator's uplink frequency band, elevating the noise floor and disrupting network performance. This interference can lead to critical issues such as dropped calls, access failures, and reduced data rates, significantly impacting the user experience and network reliability.

Non-Linearities on a Cell Site

Most Passive Intermodulation (PIM) issues stem from improper construction or maintenance practices, which lead to metal-to-metal non-linearities or galvanic corrosion. These issues can be categorized into Internal PIM and External PIM, with examples as follows:

Internal PIM occurs within the feed system (including the antenna) and is often caused by:

- Improperly torqued RF connectors: Loose or over-tightened connectors creating unstable connections.

- Metal shavings inside coax: Contaminants that interfere with signal transmission.

- Poor surface preparation: Inadequate cleaning or preparation of connectors before assembly.

- Broken solder joints: Disrupted electrical continuity within the system.

External PIM occurs beyond the antenna and is commonly caused by:

- Rusty metal surfaces: Corroded components near the antenna creating non-linear junctions.

- Loose hardware: Improperly secured components causing instability.

- Lightly touching metal surfaces: Metal components near the antenna making intermittent contact.

- Galvanic corrosion: Corrosion caused by dissimilar metals in contact.

Proper site construction and regular maintenance can help mitigate these issues, ensuring better network performance and reducing susceptibility to PIM-related interference.

An Uncontrolled Environment

The prevalence of external passive intermodulation (PIM) is notably higher on rooftop wireless sites compared to tower/pole sites primarily due to the uncontrolled environment that rooftops present. While macro sites are typically highly controlled with well-defined infrastructure and fewer surrounding interferences, rooftops are part of existing buildings and are subject to a multitude of external, often unpredictable factors.

Rooftop sites are surrounded by various metal structures such as HVAC units, powerlines, billboards, piping, railings, and even additional unrelated deployments, all of which can create PIM interference when exposed to RF signals. This makes them more susceptible to issues arising from metal-to-metal contacts and environmental changes, such as corrosion or the shifting of components due to wind or temperature variations. This limited ability to control or modify the surrounding environment contributes significantly to the higher prevalence of external PIM in rooftop deployments.

Rooftop sites are surrounded by various metal structures such as HVAC units, powerlines, billboards, piping, railings, and even additional unrelated deployments, all of which can create PIM interference when exposed to RF signals. This makes them more susceptible to issues arising from metal-to-metal contacts and environmental changes, such as corrosion or the shifting of components due to wind or temperature variations. This limited ability to control or modify the surrounding environment contributes significantly to the higher prevalence of external PIM in rooftop deployments.

The Internal vs External Crux

Troubleshooting can be challenging and crews often get deployed to sites multiple times for the same issue. Return trips have become commonplace and crews can spend countless hours removing and replacing components such as radios, jumpers and antennas only to find out the problem still exists because it was an external issue all along. The result is unnecessary hardware replacement and a lot of wasted time and money for both contractor and carrier.

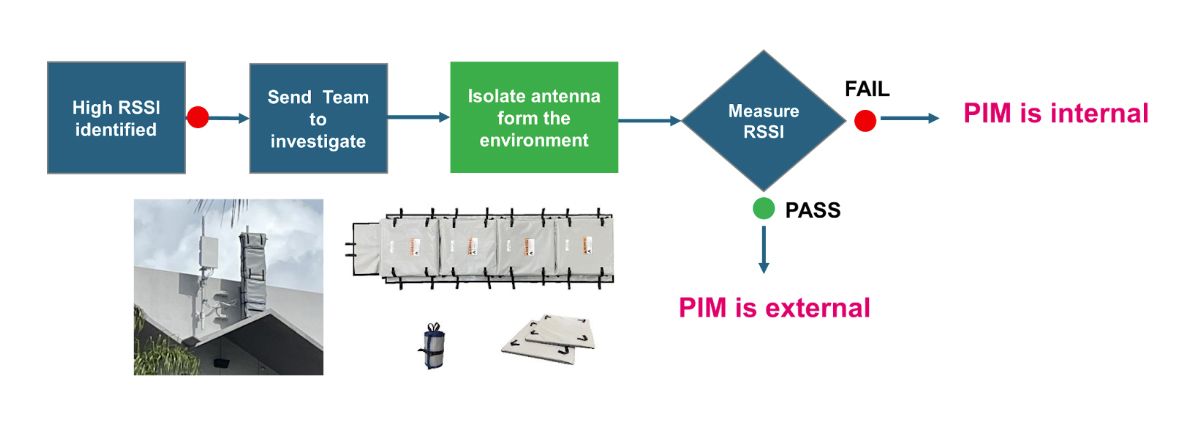

Much of this can be avoided with the right tools and a consistent process. The crux of the troubleshooting challenge occurs with the antenna, when the RF transitions from the radiating elements to the air and the outside surroundings. Is the antenna a problem, or is it the environment around the antenna? One of the best ways to answer this question is to use a tool from ConcealFab called an Absorber Kit. The absorber kit is installed directly on the antenna and isolates it from the external environment without creating excessive reflections or PIM.

By monitoring RSSI levels (Receive Signal Strength Indicator), preferably with 100% artificial loading activated on the radio, external inference is indicated if the noise goes away when the absorber kit is installed. Likewise, if the noise level remains high when the absorber kit is installed, the issue is internal (i.e. the antenna, jumper or radio are bad). Note that all the cables and connections can remain intact during this testing.

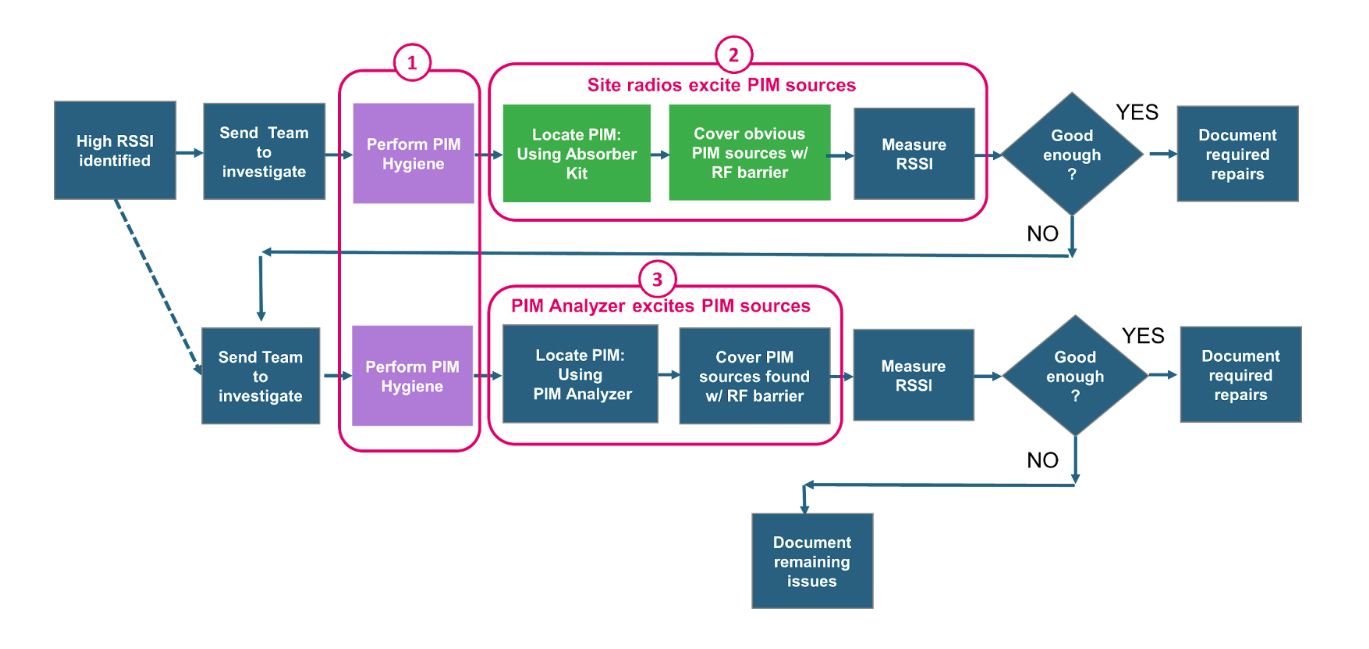

PIM Hunting Process

If the problem is internal, troubleshooting is relatively straightforward. The components can be isolated by inserting a Low PIM Load on the failing jumpers, starting at the antenna end and systematically moving it back to the radio while monitoring RSSI levels (again, preferably with 100% artificial loading activated).

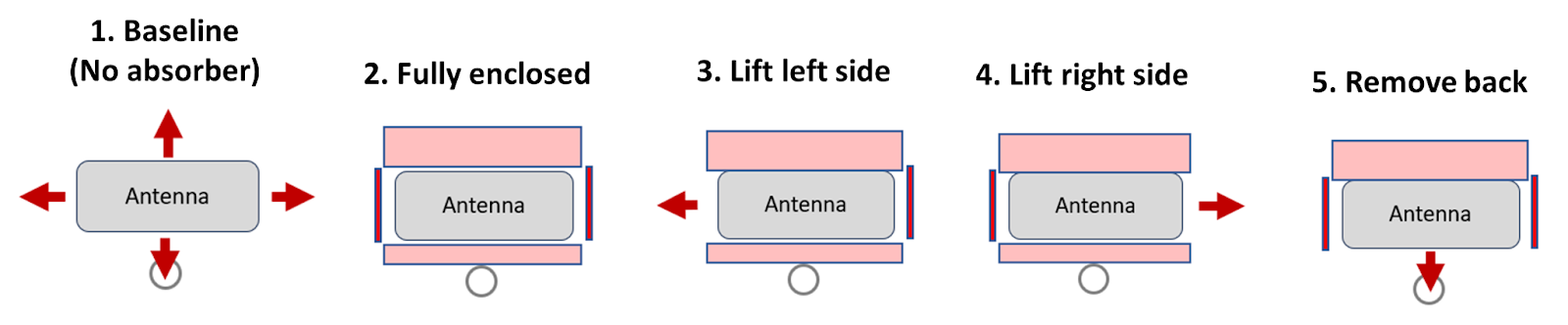

The real fun begins once the problem is confirmed to be external. First, directionality can be determined by utilizing the modular design of the absorber kit. If RSSI levels are monitored and recorded as portions of the absorber kit are removed or lifted, the direction of the PIM source can often be narrowed down to the left/right side, behind or in front of the antenna, greatly speeding up the PIM hunting process.

Once the general direction is determined, “obvious” PIM sources can systematically be covered with RF barriers such as blankets or absorbers, again while monitoring RSSI levels, and the main PIM sources can often be found by following this process. However, a particular limitation occurs when multiple PIM sources are present at roughly the same level - in this case, the RSSI level will not change when only one of the PIM sources is covered, making it difficult or impossible to identify all of the individual sources.

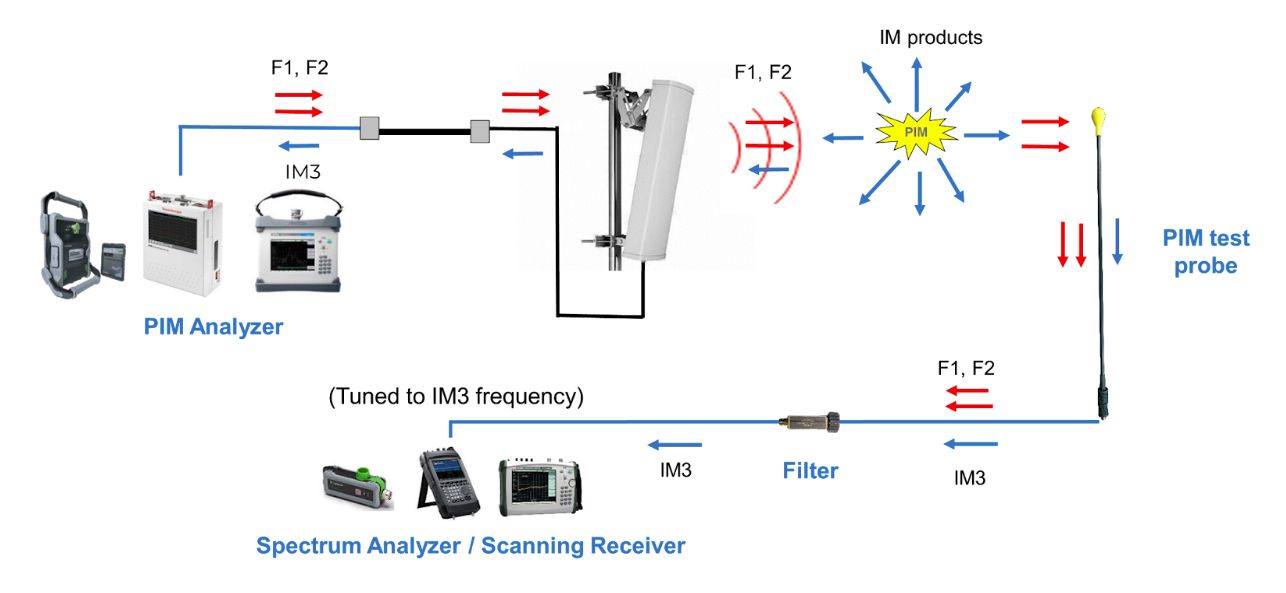

If this method is unable to identify the source of the PIM, another more sophisticated process was developed using a PIM analyzer along with a handheld spectrum analyzer paired with a PIM probe.

The PIM analyzer illuminates the PIM sources at the site, measures the magnitude of PIM being generated and adds a Distance to PIM (DTP) measurement that can be utilized to aid the hunt. The secondary mobile receiver is tuned to the same IM3 frequency being measured by the PIM analyzer and attached to a PIM Probe. When the probe tip is close to a source, the sound from the receiver becomes stronger. PIM sources can then be hunted like searching for coins on a beach with a metal detector. A bandpass filter is essential between the PIM probe and the spectrum analyzer to prevent the F1 and F2 test tones from mixing within the receiver. Without this filter, high levels of PIM could be generated internally, creating the false impression that PIM is originating from multiple sources.

Crews with the proper equipment and training can follow this process and identify each of the PIM sources that may be contributing to the high levels of uplink noise at the site.

Proper PIM Hygiene Comes First

Regardless of the method used for PIM hunting, the first step any crew should take upon arriving at a site is to assess PIM hygiene. Maintaining effective PIM hygiene accelerates the overall PIM hunting process and can sometimes resolve issues entirely. Many PIM hygiene concerns are straightforward to identify and address with proper inspection and basic tools, making it a cost-effective practice that provides lasting benefits to the site.

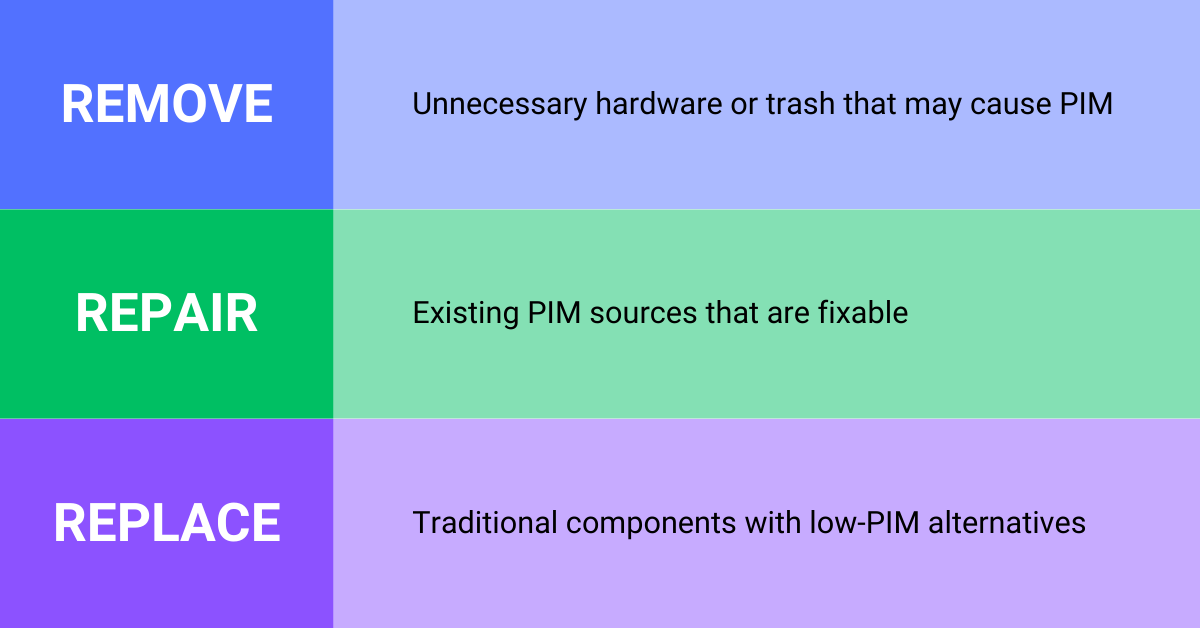

PIM Hygiene is defined as the elimination of “known” PIM sources near antennas. PIM hygiene follows a simple framework: Remove, Repair, and Replace.

That is Remove unwanted hardware, Repair PIM sources that can be fixed, and Replace traditional components with Low-PIM alternatives. The primary focus is within the “high risk PIM zone” which encompasses an area roughly 10 feet behind, below and above the antenna for typical low and mid-band deployments. Begin by removing unnecessary hardware, debris, or trash that may cause PIM. Next, tighten any loose hardware, and identify lightly touching metal surfaces that could be eliminated or adjusted to prevent contact. Clean rusty, corroded surfaces by removing loose metal and burs, wiping them with a solvent to remove dust and applying a cold galvanizing spray/paint. Avoid dissimilar metals touching. In particular, avoid stainless steel parts against galvanized steel parts as the galvanic mismatch creates a junction where PIM can be generated. Finally, replace all traditional components like metal snap-ins and hose clamps with low-PIM alternatives.

By adhering to this structured approach, crews can systematically address and mitigate PIM. Furthermore, operators must require these steps to improve performance, prevent future issues and help ensure optimal performance.

PIM Mitigation Options

For many rooftop sites, there are PIM sources that simply cannot be avoided, particularly in front of the antennas. Even when an operator and/or contractor has followed the build standards, used low PIM hardware, and performed thorough PIM hygiene, they have little control over the building structures outside of the lease space such as roofing materials/construction, placement of structures like HVAC systems, sky lights, solar panels, etc. Add to that zoning restrictions on height and visibility which may require concealment solutions that further complicate the RF environment near the antennas. In these cases, once the PIM source has been identified, the next challenge is how to eliminate or reduce it.

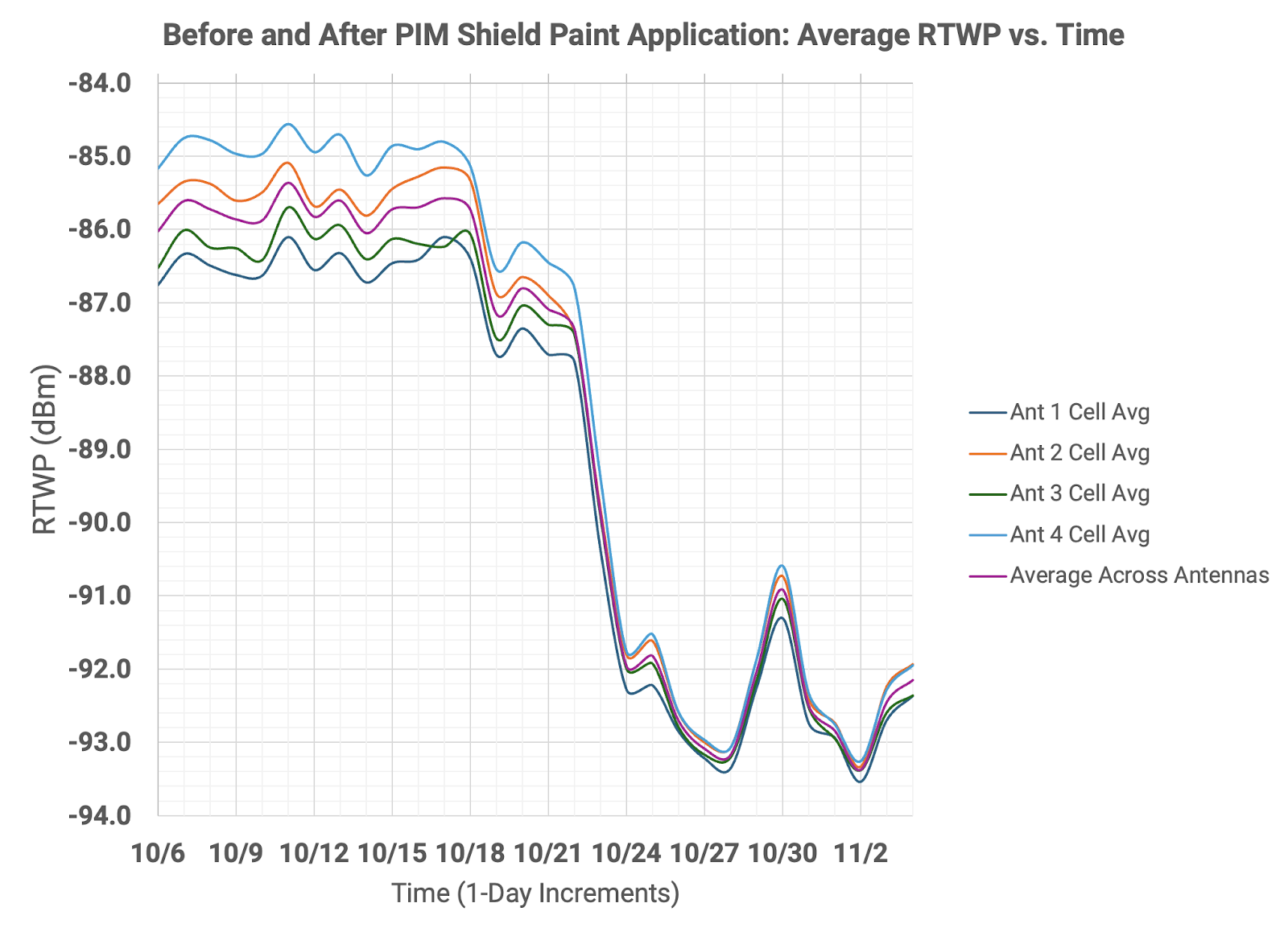

PIM Paint has proven to be an effective RF barrier for many of the most common sources such as parapet walls, roof flashings, and the roof membrane itself. It is particularly suited for large surface areas but is also effective on smaller structural members. It is common to achieve greater than 17dB of RF attenuation with two coats of paint which can result in a significant reduction in uplink noise for the carrier and major improvements in performance metrics such as data throughput and access failures.

Further details and guidance on the application of PIM Paint can be found here.

The Path Forward: Ensuring a Reliable Network Experience

As wireless demand continues to grow and new frequencies are added into networks, external PIM will remain a persistent and increasingly prevalent issue. Addressing these challenges head-on is essential for preserving the reliability, efficiency, and performance of wireless deployments. With the right tools and training and strict adherence to a proven troubleshooting process, rooftop PIM can be mitigated. The next major step will require a more proactive approach to site selection, antenna placement, material guidelines and further attention to detail during installation. This means a coordinated effort for operators with changes across the organization in site acquisition, RF design, site construction, and RF optimization. But the pay-off will be more efficient use of available spectrum resulting in improved overall network performance.

Resources

- PIM Absorber Kits

- PIM Absorber Kit User Guide

- PIM Paint Application Note

- Proactively Dealing with PIM Interference from ConcealFab®

- PIM Hygiene, Troubleshooting, & Advanced PIM Hunting Certification from ConcealFab®

Drew Martin, Sales Support Engineer at ConcealFab®

Drew Martin is a seasoned professional with over 15 years of experience in the wireless telecommunications industry. With extensive expertise in cell site troubleshooting, PIM hunting, and technical product support, Drew has established himself as a trusted resource for optimizing network performance and solving complex technical challenges.

As a dedicated trainer, Drew has educated thousands of professionals - from RF Engineers to Cell Site Technicians - on Sweep and PIM Fundamentals, as well as Advanced External PIM Hunting. His hands-on approach and deep technical knowledge have helped countless teams enhance their skills and achieve operational excellence.

Drew’s technical acumen extends to managing large-scale field operations, diagnosing and resolving interference issues, and developing innovative solutions to improve network reliability. Known for his ability to bridge the gap between technical complexity and actionable solutions, Drew has built a reputation for delivering results in even the most demanding environments.

He holds a degree from Embry-Riddle Aeronautical University, where he honed the problem-solving and analytical skills that underpin his professional success. Outside of work, Drew is an avid mountain biker, hiker, and skier who brings the same energy and passion to his outdoor pursuits as he does to his professional endeavors

Resources

Register for Updates & Savings

By submitting your email address, you agree to receive specials, news, announcements and various email communications from Valmont Telecommunications, Inc.